Resin ea polyvinyl chloride e emisitsoeng

Resin ea polyvinyl chloride e emisitsoeng,

PVC SG5, PVC SG6, PVC SG8,

Resin ea polyvinyl chloride e emisitsoeng

SG-1: K boleng 77-75 tekanyo ea karolelano ea polymerization

SG-2: K boleng 74-73 tekanyo ea karolelano ea polymerization

SG-3: K boleng 72-71 karolelano ea tekanyo ea polymerization 1350-1250

SG-4: K boleng 70-69 karolelano polymerization degree 1250-1150

SG-5: K boleng 68-66 Karolelano ea tekanyo ea polymerization 1100-1000

SG-6: K boleng 65-63 Karolelano ea tekanyo ea polymerization 950-850

SG-7: K boleng 62-60 karolelano polymerization degree 850-750

SG-8: K boleng 59-55 Karolelano ea tekanyo ea polymerization 750-650

Lisebelisoa tse kholo:

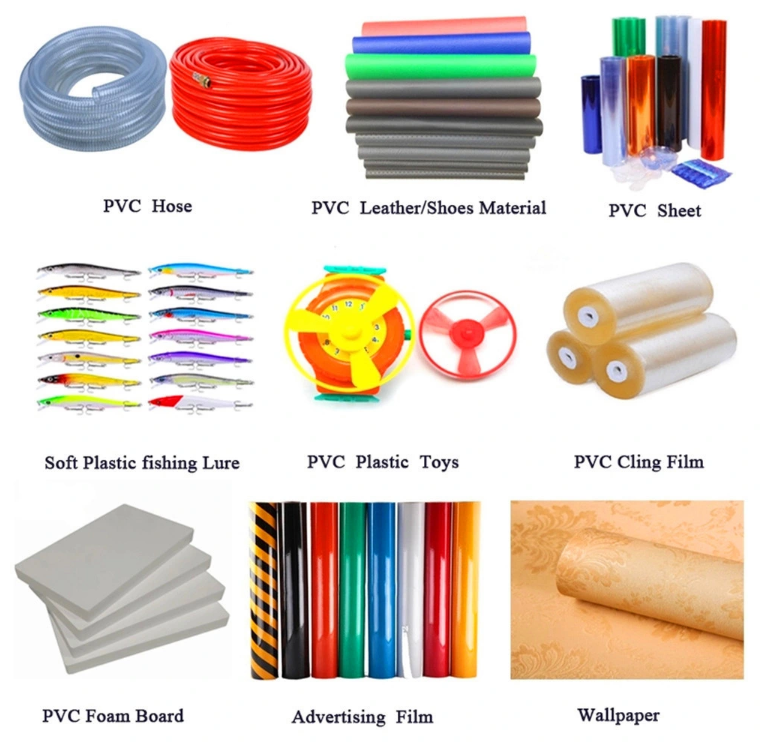

Resin ea PVC e ka sebetsoa ka lihlahisoa tse fapaneng tsa polasetiki, ho latela ts'ebeliso ea eona e ka aroloa ka lihlahisoa tse bonolo le tse thata ka mekhahlelo e 'meli, haholo-holo e sebelisetsoang tlhahiso ea lipampiri tse pepeneneng, lisebelisoa tsa phala, likarete tsa khauta, lisebelisoa tsa tšelo ea mali, liphaephe tse bonolo, tse thata. , lipoleiti, mamati le Windows, profiles, lifilimi, lisebelisoa tsa ho kenya motlakase, ho tšela cable, lisebelisoa tsa tšelo ea mali joalo-joalo.

1.PVC lihlahisoa tse bonolo le tse thata ka kakaretso - ts'ebeliso ea extruder e ka hatelloa ka har'a li-tubes tse bonolo le tse thata, likhoele, lithapo, joalo-joalo; Ho sebelisa mochini oa ho bopa ka ente ka mefuta e fapaneng, e ka etsoa meqathatso ea polasetiki, soles, slippers, toys, le litlhoko tse ling tsa letsatsi le letsatsi le likoloi le lisebelisoa tsa motlakase.

2.PVC phala e thata le profil - ha e bapisoa le lipolasetiki tse ling, PVC e na le khanyetso e babatsehang ea botsofali, matla a ts'usumetso e phahameng le ho tiea, theko e tlaase, e loketseng liphaephe tsa drainage le liphaephe tse ling tsa mohaho, le litlaleho tsa profil.

Filimi ea 3.PVC - PVC le li-additives tse tsoakiloeng, tse entsoeng ka polasetiki, li sebelisa mochine oa calendering tse tharo kapa tse 'nè ka botenya bo itseng ba filimi e hlakileng kapa e mebala, ka mokhoa ona oa ho sebetsana le filimi, e fetoha filimi ea calendering. raincoats, tablecloths, likharetene, lintho tsa ho bapala inflatable, joalo-joalo.Wide bonaletsang filimi ka sebelisoa bakeng sa greenhouses, greenhouses polasetiki le mulch polasetiki.Bidirectionally otlolla filimi, thepa ea mocheso shrinkage, e ka sebelisoa bakeng sa shrink ambalaji.

Lihlahisoa tse koahetsoeng ka 4.PVC - letlalo la maiketsetso le tšehelitsoeng ke PVC le kopantsoeng le lesela kapa pampiri, ebe le etsoa polasetiki ka likhato tse fetang 100 tsa Celsius. substrate e phuthoa ka ho toba ke calender ka botenya bo itseng ba lakane e bonolo, ebe e hatelloa holim'a mohlala.Letlalo la maiketsetso le ka sebelisoa ho etsa lisutuk'heise, mekotla, likoahelo tsa libuka, li-sofa le li-cushion tsa koloi, le letlalo la fatše, le sebelisoang e le thepa ea fatše. bakeng sa meaho.

Lihlahisoa tsa foam tsa 5.PVC - motsoako o bonolo oa PVC, eketsa tekanyo e nepahetseng ea sesebelisoa sa foam ho etsa thepa ea lakane, foam foam bakeng sa polasetiki ea foam, e ka sebelisoa e le li-slippers tsa foam, meqathatso, insole, le lisebelisoa tsa ho paka li-buffer. extruder e thehiloeng ka poleiti e thata ea PVC e foaming le profil, e ka nka sebaka sa teko ea lehong, ke mofuta o mocha oa thepa ea moaho.

6.PVC transparent sheet - PVC hammoho le phello modifier le stabilizer, ka mor'a ho kopanya, plasticizing, calendering 'me e be transparent sheet.Thermoforming ka etsoa ka tšesaane leboteng bonaletsang setshelo kapa sebelisoa bakeng sa vacuum blister ambalaji.Ke thepa e babatsehang ea ho paka le ho khabisa.

7 PVC ka thata poleiti le poleiti - PVC eketsa stabilizer, lubricant le filler, ka mor'a ho kopanya, extruder ka extrude mefuta e fapaneng ya caliber ea phala e thata, phala e bōpehileng joaloka, bellows, sebelisoa e le phala fatše, phala ea metsi, terata sleeve kapa litepisi handrail.Hard sheets. tsa botenya tse fapa-fapaneng li ka etsoa ka ho hatella li-sheet laminated sheets.Letlapa le ka khaoloa ka sebopeho se lakatsehang, ebe molamu oa tjheseletsa oa PVC o sebelisoa ho kenya litanka tse sa tšoaneng tsa polokelo ea lik'hemik'hale, likotopo tsa moea le lijana tse nang le moea o chesang.

8.PVC tse ling - mamati le lifensetere li kopantsoe ka thepa e thata ea sebopeho se ikhethileng. Linaheng tse ling, e nkile 'maraka oa mamati le lifensetere tse nang le mamati a lehong le lifensetere tsa aluminium; thepa ea lehong ea ho etsisa, tlhahiso ea thepa ea kaho ea tšepe (leboea, lebopong la leoatle. );Setshelo se sekoti.

Lintlha tsa sehlahisoa

PVC ke khutsufatso ea polyvinyl chloride.Resin ke lisebelisoa tse atisang ho sebelisoa ha ho etsoa lipolasetiki le rabara.Resin ea PVC ke phofo e tšoeu e atisang ho sebelisoa ho hlahisa thermoplastics.Ke thepa ea maiketsetso e sebelisoang haholo lefatšeng kajeno.Polyvinyl chloride resin e na le litšobotsi tse ikhethang joalo ka lisebelisoa tse ngata tse tala, theknoloji ea tlhahiso e holileng, theko e tlase le mefuta e mengata ea ts'ebeliso.Ho bonolo ho e sebetsa mme e ka sebetsoa ka ho bopa, ho laminate, ho bopa ka ente, extrusion, calendering, ho bopa le mekhoa e meng.E na le thepa e ntle ea 'mele le ea lik'hemik'hale, e sebelisoa haholo indastering, kaho, temong, bophelong ba letsatsi le letsatsi, ho paka, motlakase, lits'ebeletso tsa sechaba le masimo a mang.Li-resin tsa PVC hangata li na le khanyetso e phahameng ea lik'hemik'hale.E matla haholo mme e hanana le metsi le abrasion.Polyvinyl chloride resin (PVC) e ka sebetsoa ka lihlahisoa tse fapaneng tsa polasetiki.PVC ke polasetiki e bobebe, e theko e tlase ebile e baballang tikoloho.

Likaroloana

PVC ke e 'ngoe ea li-resin tsa thermoplastic tse sebelisoang haholo.E ka sebelisoa ho etsa lihlahisoa tse nang le boima bo phahameng le matla, joalo ka liphaephe le li-fittings, mamati a profild, lifensetere le lipampiri tsa ho paka.E ka boela ea etsa lihlahisoa tse bonolo, tse kang lifilimi, maqephe, lithapo tsa motlakase le likhoele, liboto tsa fatše le letlalo la maiketsetso, ka ho eketsa li-plasticizers.

Mekhahlelo

| Mephato | QS-650 | S-700 | S-800 | S-1000 | QS-800F | QS-1000F | QS-1050P | |

| Karolelano ea tekanyo ea polymerization | 600-700 | 650-750 | 750-850 | 970-1070 | 600-700 | 950-1050 | 1000-1100 | |

| Boima bo bonahalang, g/ml | 0.53-0.60 | 0.52-0.62 | 0.53-0.61 | 0.48-0.58 | 0.53-0.60 | ≥0.49 | 0.51-0.57 | |

| Likahare tsa Volatiles (metsi a kenyelelitsoe),%, ≤ | 0.4 | 0.30 | 0.20 | 0.30 | 0.40 | 0.3 | 0.3 | |

| Plasticizer absorption ea 100g resin, g, ≥ | 15 | 14 | 16 | 20 | 15 | 24 | 21 | |

| VCM masalla, mg/kg ≤ | 5 | 5 | 3 | 5 | 5 | 5 | 5 | |

| Litlhahlobo % | 0.025 limilimithara letlooeng% ≤ | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 0.063m letlooeng% ≥ | 95 | 95 | 95 | 95 | 95 | 95 | 95 | |

| Nomoro ea leihlo la litlhapi, No./400cm2, ≤ | 30 | 30 | 20 | 20 | 30 | 20 | 20 | |

| Palo ea likaroloana tse sa hloekang, Che., ≤ | 20 | 20 | 16 | 16 | 20 | 16 | 16 | |

| Bosoeu (160ºC, metsotso e 10 hamorao), %, ≥ | 78 | 75 | 75 | 78 | 78 | 80 | 80 | |

| Lisebelisoa | Lisebelisoa tsa ho bopa ka ente, lisebelisoa tsa liphaephe, lisebelisoa tsa ho khalendara, li-profiles tse thata tse nang le maholiotsoana, profaele e thata ea leqephe la moaho. | Leqephe le thata, Lipoleiti, Lisebelisoa tsa Mokatong, Lining Epidural, Likarolo tsa Lisebelisoa tsa Motlakase, Likarolo tsa Koloi. | Filimi e pepeneneng, liphutheloana, khateboto, likhabinete le mekato, lintho tsa ho bapala, libotlolo le lijana | Maqephe, Matlalo a Maiketsetso, Lisebelisoa tsa Liphaephe, Profiles, Bellows, liphaephe tse sireletsang thapo, lifilimi tsa ho paka | Lisebelisoa tsa Extrusion, Lithapo tsa Motlakase, Lisebelisoa tsa Cable, Lifilimi tse Bonolo le Lipoleiti | Lipampiri, Lisebelisoa tsa Khalendara, Lisebelisoa tsa ho Khalendara Liphaephe, Lisebelisuoa tse Itšireletsang tsa Lithapo le Lithapo | Lipeipi tsa ho nosetsa, lipeipi tsa metsi a nooang, lipeipi tsa foam-core, lipeipi tsa likhoerekhoere, lipeipi tsa terata, li-profiles tse thata. | |

Sephutheloana

(1) Ho paka: 25kg net / pp mokotla, kapa mokotla oa pampiri oa kraft.

(2) Ho roala palo : 680Bags/20′container, 17MT/20′container .

(3) Ho kenya palo : 1120Bags/40′container, 28MT/40′container .