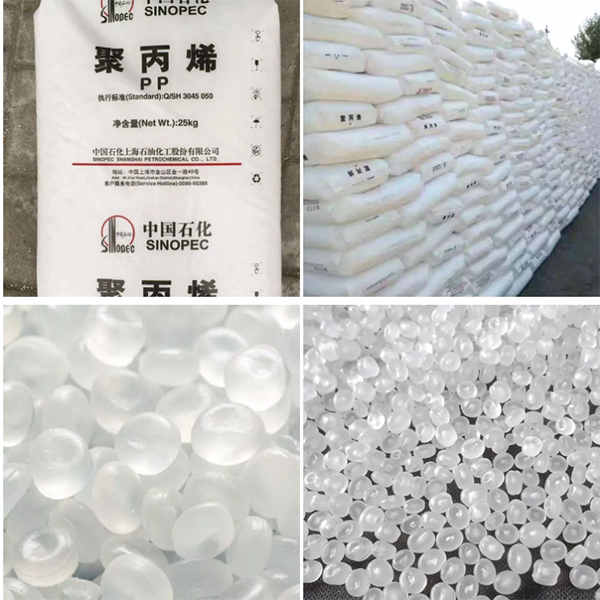

PP resin

Polypropylene ke resin ea maiketsetso e entsoeng ka polymerization ea propylene (CH3—CH = CH2) e nang le H2 e le mofetoleli oa boima ba limolek'hule.Ho na le li-stereomer tse tharo tsa PP - isotactic, atactic le syndiotactic.PP ha e na lihlopha tsa polar ebile e na le thepa e ntle ea ho kenya motlakase.Sekhahla sa eona sa ho monya metsi se ka tlase ho 0.01%.PP ke polymer ea semi-crystalline e nang le botsitso bo botle ba lik'hemik'hale.E tsitsitse ho lik'hemik'hale tse ngata ntle le li-oxidizer tse matla.Lisebelisoa tsa inorganic acid, alkali le letsoai ha li na phello e senyang ho PP.PP e na le khanyetso e ntle ea mocheso le letsoalo le tlase.Sebaka sa eona sa ho qhibiliha se ka bang 165 ℃.E na le matla a phahameng a ho tsieleha le ho thatafala ha holimo le khatello e ntle ea khatello ea tikoloho.E khona ho mamella 120 ℃ e sa khaotse.

Sinopec ke mohlahisi e moholo ka ho fetisisa oa PP naheng ea China, matla a eona a PP a nka karolo ea 45% ea kakaretso ea naha.Khamphani hajoale e na le limela tse 29 tsa PP ka ts'ebetso e tsoelang pele (ho kenyeletsoa le tse ntseng li hahuoa).Theknoloji e sebelisoang ke likarolo tsena e kenyelletsa ts'ebetso ea HYPOL ea Mitsui Chemical, mokhoa oa khase ea Amoco, ts'ebetso ea Basell's Spheripol le Spherizone le ts'ebetso ea mohato oa khase ea Novolen.Ka bokhoni ba eona bo matla ba ho etsa lipatlisiso tsa mahlale, Sinopec e ikemetse ka boikemelo ba moloko oa bobeli oa loopprocess bakeng sa tlhahiso ea PP.

Lintlha tsa PP

1.Tekanyo e lekanyelitsoeng e nyane, ke 0.89-0.91 feela, e leng e 'ngoe ea mefuta e bobebe ka ho fetisisa ea polasetiki.

2. thepa e ntle ea mechine, ntle le ho hanyetsa tšusumetso, lisebelisoa tse ling tsa mechine li molemo ho feta polyethylene, ts'ebetso ea ho bōpa e ntle.

3.E na le mocheso o phahameng oa ho hanyetsa 'me mocheso o tsoelang pele oa tšebeliso o ka fihla ho 110-120 °C.

4.mehato e ntle ea lik'hemik'hale, hoo e batlang e se na metsi, 'me ha e sebetsane le lik'hemik'hale tse ngata.

5.thepa e hloekile, ha e na chefo.

6.motlakase oa motlakase o molemo.

Referense e sebelisoang hangata bakeng sa sehlopha sa PP

(ka lebaka la lintlha tsa 'maraka le kemiso ea tlhahiso, mofuta oa nnete o kanna oa fapana, ka kopo ikopanye le rona bakeng sa netefatso e khethehileng ea sehlopha)

| Sehlopha | Kereiti | MFI | Botenya | Lisebelisoa tse kholo |

| Homopolymer - Extrusion | F103 | 3.3 | 0.9 | BOPP Film Grade - Sepheo se Akaretsang, Lamination & Metallizable lifilimi |

| T30S | 3.3 | 0.9 | Litheipi tsa Raffia, mekotla e lohiloeng bakeng sa ho paka menontsha, samente, li-polymers, tšehetso ea k'hapete, FIBC joalo-joalo. | |

| T103 | 3.3 | 0.9 | Likopi tsa Thermoformed, Lijana le Lintho tse ling tse lahliloeng | |

| F110 | 11 | 0.9 | Lifilimi tsa TQ le Cast bakeng sa Packaging ea Morero o Akaretsang joalo-joalo. | |

| Homopolymer - Ente Molding | M103 | 3 | 0.9 | Kakaretso ea Ente Molding |

| M106 | 6 | 0.9 | Kakaretso ea Ente Molding | |

| M108 | 8 | 0.9 | Kakaretso ea Ente Molding | |

| M110 | 10 | 0.9 | General Purpose Ente Molding, Furniture jj. | |

| Impact Copolymer - Ente Molding | M304 | 3.5 | 0.9 | Likarolo tsa Likoloi, Kereiti, Lipail, Thepa ea ka tlung joalo-joalo. |

| M307 | 7 | 0.9 | Kakaretso ea Ente Molding | |

| M310 | 10 | 0.9 | Mabokose a Battery | |

| M311T | 10 | 0.9 | Ho kopanya, Likarolo tsa Likoloi, Meroalo le Lisebelisoa tsa Indasteri | |

| M312 | 12 | 0.9 | Metsoako, Likarolo tsa Indasteri, Likarolo tsa Likoloi, Lithōle, Lipaele, Lisebelisoa tsa Ntlo, Lintho tsa Bohloeki joalo-joalo. | |

| M315 | 15 | 0.9 | Kakaretso ea Ente Molding | |

| M325 | 25.0 | 0.9 | Motsoako, Likarolo tsa Likoloi, Lisebelisoa tsa Ntlo, Likarolo tsa Lisebelisoa, Coating ea Extrusion | |

| M340 | 40 | 0.9 | Lisebelisoa le Thepa e Tšoeu, Karolo ea Likoloi, Motsoako, TWIM | |

| Random Copolymer - Blow Molding | B202S | 1.9 | 0.9 | Botlolo le Lijana tsa Lihlahisoa tsa Bongaka le tse Bonahalang (mohlala, Libotlolo tsa IV tsa Mokelikeli) joalo-joalo |

| B200 | 1.9 | 0.9 | Sepheo se Akaretsang Phatlalatso ea Lintho tse Molded & Thermoformed, Sheets for Files & Folders. | |

| M212S | 12 | 0.9 | Lits'oants'o tse hlakileng tse phahameng, lintho tsa ka tlung, syringe ea ente, lihlahisoa tsa laboratori le libotlolo tsa ISBM. |

Kopo

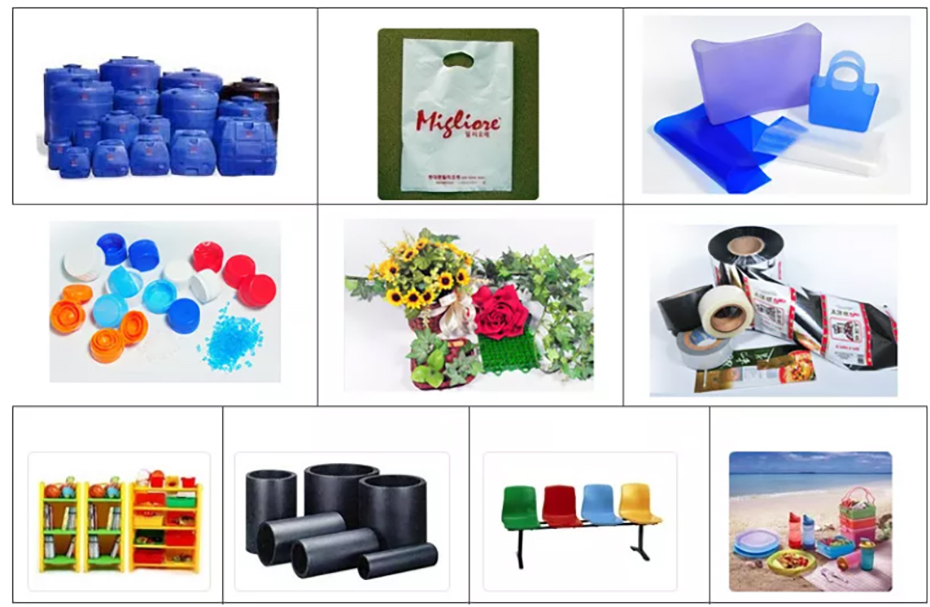

PP e na le lisebelisoa tse fapaneng.E loketse mekhoa e mengata ea ts'ebetso e joalo ka ho bopa ka ente, ho bopa ha extrusion le ho bopa 'me e sebelisoa haholo indastering ea masela, liphutheloana, lisebelisoa tsa ntlo tsa motlakase, liindasteri tsa likoloi le tsa thekiso ea matlo.Limela tsa Sinopec PP li na le mahlale a fapaneng a ho hlahisa homopolymer, copolymer e sa sebetseng le phello ea copolymer PP e nang le thepa e ikhethang.Lihlahisoa tsena li kenyelletsa filimi ea BOPP, filimi ea CPP, fiber, pipe, coating, khoele le lihlahisoa tse entsoeng ka ente.

1. Fiber (K'hapete, Masela, Nonwoven, Upholstery, joalo-joalo)

2.Film ( mekotla ea mabenkele, filimi ea ho lahla, filimi ea multilayer, joalo-joalo)

3.Blow Molding (Bongaka & Cosmetic setshelo, Lubricant & Paint setshelo, joalo-joalo)

4.Extrusion Molding (Sheet, Pipe, Wire & Cable, joalo-joalo)

5.Ente Molding (Likoloi, Elektronike, Kaho, Thepa ea ntlo, Thepa ea ka tlung,

Lintho tsa ho bapala, joalo-joalo)

Sephutheloana

Ka mokotleng oa 25kg, 16MT ho 20fcl e le 'ngoe ntle le pallet kapa 26-28MT ho 40HQ e le' ngoe e se nang pallet kapa mokotla oa jumbo oa 700kg, 26-28MT ho 40HQ e le 'ngoe ntle le pallet.