PVC e entsoe ka vinyl chloride ka polymerization ea mahala.Ka ho emisoa ha polymerization, emulsion polymerization le polymerization e ngata, polymerization ea ho emisoa ke mokhoa o ka sehloohong, o ikarabellang bakeng sa hoo e ka bang 80% ea kakaretso ea tlhahiso ea PVC.Ka indasteri, mokhoa oa tlhahiso ea PVC ka kakaretso o itšetlehile ka mokhoa oa ho fumana vinyl chloride monomer ho khetholla, e ka aroloa ka mokhoa oa khalsiamo carbide, mokhoa oa ethylene le o tsoang linaheng tse ling (EDC, VCM) mokhoa oa monomer (ka tloaelo o bitsoa mokhoa oa ethylene le mokhoa oa monomer o tsoang linaheng tse ling) .Ho ea ka mekhoa e fapaneng ea tlhahiso, phofo ea PVC e arotsoe ka: resin ea bokahohle ea PVC, resin ea PVC e nang le tekanyo e phahameng ea polymerization, crosslinking PVC resin.Universal PVC resin e thehoa ke polymerization ea vinyl chloride monomer tlas'a ketso ea initiator;Resin ea PVC e nang le tekanyo e phahameng ea polymerization e bua ka resin e entsoeng ka ho eketsa ketane e ntseng e eketseha ka har'a tsamaiso ea polymerization ea vinyl chloride monomer;Crosslinked PVC resin ke resin e entsoeng ka polymerized ka ho kenyelletsa motsoako oa crosslinking o nang le diene le polyene tsamaisong ea polymerization ea vinyl chloride monomer.

Ho emisoa ha polyvinyl chloride resin Moetso oa hajoale:

Sg-1: K 77-75 tekanyo ea karolelano ea polymerization

Sg-2: K 74-73 tekanyo ea karolelano ea polymerization

Sg-3: K boleng 72-71 Karolelano ea tekanyo ea polymerization 1350-1250

Sg-4: boleng ba K 70-69 karolelano ea tekanyo ea polymerization 1250-1150

Sg-5: K boleng 68-66 Karolelano ea tekanyo ea polymerization 1100-1000

Sg-6: K boleng 65-63 Karolelano ea tekanyo ea polymerization 950-850

Sg-7: K boleng 62-60 tekanyo ea karolelano ea polymerization 850-750

Sg-8: K boleng 59-55 tekanyo ea karolelano ea polymerization 750-650

Lisebelisoa tsa mantlha:

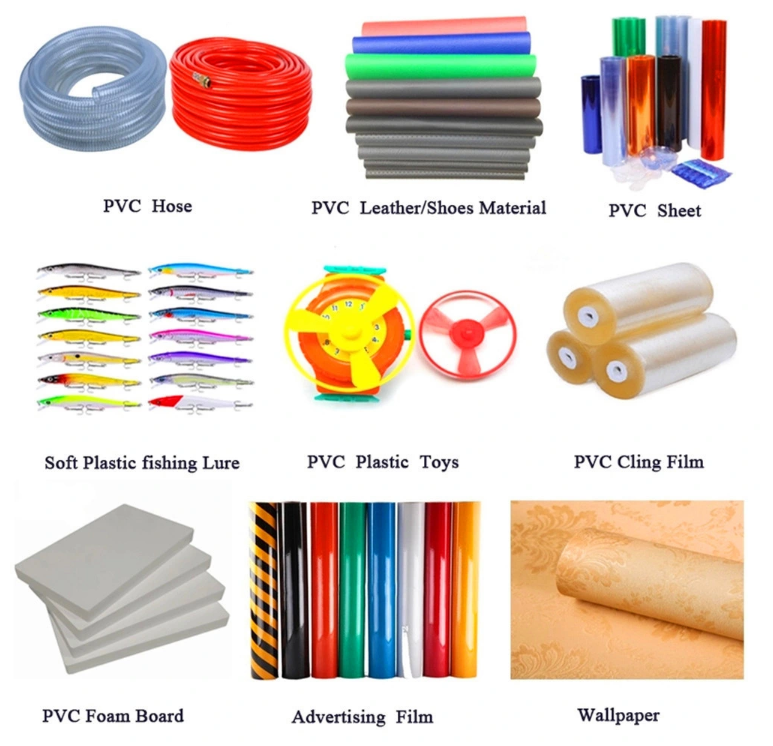

PVC resin e ka sebetsoa ka lihlahisoa tse fapaneng tsa polasetiki, ho latela ts'ebeliso ea eona e ka aroloa ka mekhahlelo e 'meli ea lihlahisoa tse bonolo le tse thata, tse sebelisoang haholo ho hlahisa likotoana tse pepeneneng, lisebelisoa tsa phala, likarete tsa khauta, lisebelisoa tsa tšelo ea mali, tse bonolo le tse thata. liphaephe, lipoleiti, mamati le Windows, profiles, lifilimi, lisebelisoa tsa ho kenya motlakase, sheath ea cable, lisebelisoa tsa tšelo ea mali, joalo-joalo.

1.PVC ka kakaretso lihlahisoa tse bonolo le tse thata - ho sebelisa extruder ho ka hatelloa ka liphaephe tse bonolo le tse thata, lithapo, lithapo, joalo-joalo;Ka mochini oa ente ea ente le hlobo e fapaneng, e ka etsoa meqathatso ea polasetiki, soles, slippers, lintho tsa ho bapala, litlhoko tsa letsatsi le letsatsi le lisebelisoa tsa koloi le tsa motlakase.

2 PVC phala e thata le profil - e amanang le lipolasetiki tse ling, ho hanyetsa botsofali ba PVC ke ntho e babatsehang, matla a tšusumetso e phahameng le ho tiea, theko e tlaase, e loketseng liphaephe tsa drainage le phala e meng ea kaho, le profil profile.

Filimi ea 3 ea PVC - PVC le li-additives tse tsoakiloeng, polasetiki, tšebeliso ea mochine o rollang tse tharo kapa tse 'nè ka botenya bo itseng ba filimi e hlakileng kapa e mebala, ka mokhoa ona oa ho sebetsana le filimi, e fetoha filimi ea calendering.E ka boela ea khaoloa, mekotla ea ho paka ka mocheso, li-raincoats, masela a tafole, likharetene, lintho tsa ho bapala tse inflatable joalo-joalo.Filimi e pharaletseng e hlakileng e ka sebelisoa bakeng sa sethopo, sethopo sa polasetiki le filimi ea polasetiki.Ka mor'a ho otlolla filimi ka mahlakoreng a mabeli, thepa ea ho fokotseha ha mocheso, e ka sebelisoa bakeng sa liphutheloana tsa shrink.

Lihlahisoa tse 4 tsa PVC tse koahetsoeng - ka karolo e ka tlaase ea letlalo la maiketsetso ke PVC e ferekanngoa ka lesela kapa pampiri, ebe ka likhato tse 100 tsa Celsius ka holimo ho polasetiki.Hape e ka ba PVC le filimi e thusang ea calendering, ebe e hatelloa hammoho le substrate.Letlalo la maiketsetso le se nang substrate le kenngoa ka ho toba ka mochine oa calendering ka har'a botenya bo itseng ba letlapa le bonolo, ebe le hatelloa holim'a mohlala.Matlalo a maiketsetso a ka sebelisoa ho etsa lisutuk'heise, mekotla, likoahelo tsa libuka, li-sofa le li-cushion tsa koloi, le letlalo la fatše, le sebelisoang e le thepa ea mohaho oa fatše.

Lihlahisoa tsa foam tsa 5.PVC - motsoako o bonolo oa PVC, eketsa tekanyo e nepahetseng ea sesebelisoa sa foam ho etsa lisebelisoa tsa pampiri, foam foam bakeng sa polasetiki ea foam, li-slippers tsa foam, meqathatso, li-insoles, le lisebelisoa tsa ho paka tse thibelang li-buffer.Hape KA SEBELISA extruder FOUNDATION ka tlaase foaming ka thata PVC lakane le profil, ka nka sebaka teko lehong, ke mofuta o mocha oa thepa ea mohaho.

6 Letlapa le pepeneneng la PVC - PVC e eketsa phetoho ea phello le stabilizer, ka mor'a ho kopanya, ho etsa polasetiki, ho etsa calendering le ho ba letlapa le hlakileng.Tšebeliso ea sebopeho se chesang se ka etsoa ka lijana tse pepeneneng tse tšesaane kapa tsa sebelisoa bakeng sa ho paka li-vacuum blister, ke lisebelisoa tse ntle tsa ho paka le lisebelisoa tse khabisitsoeng.

7 PVC ka thata poleiti le poleiti - PVC stabilizer, lubricant le filler, ka mor'a ho kopanya, ka extruder ka extruded mefuta e fapaneng caliber ea phala e thata, phala e khethehileng e bōpehileng joaloka, melumo, sebelisoa e le pompong, phala e nooang, terata sleeve kapa handrail litepisi.Ho hatella ho chesang ha pampiri ea calender ho ka etsa maqephe a thata a mefuta e fapaneng.poleiti ka khaola ka sebopeho a lakatsa, 'me joale tšebeliso ea li-electrode PVC le chesang moea tjheseletsa ka mefuta e fapaneng ya lik'hemik'hale kutu manganga litanka polokelo, ducts moea le lijana.

8.PVC tse ling - mamati le Windows li entsoe ka thepa e thata e nang le sebōpeho se khethehileng.Linaheng tse ling e bile le mamati a lehong le Windows aluminium Windows le mamati a mang a tloaelehileng le 'maraka oa Windows;Ho etsisa thepa ea lehong, thepa ea mohaho oa tšepe ea moloko (leboea, lebōpong la leoatle);Setshelo se sekoti.

Nako ea poso: Aug-08-2022