masterbatch e fetotsoeng bakeng sa likhahla tse phahameng tsa polyethylene tse nang le bophara bo boholo

masterbatch e fetotsoeng bakeng sa likhahla tse phahameng tsa polyethylene tse nang le bophara bo boholo,

HDPE bakeng sa tlase, HDPE bakeng sa phala e koetsoeng,

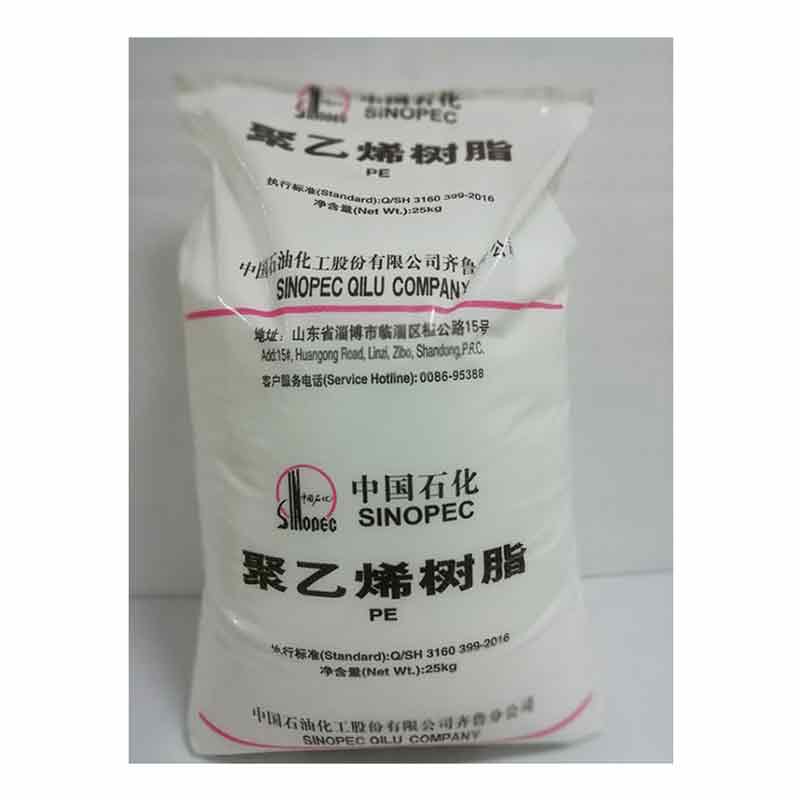

Sehlahisoa sena se hlahisoa ho sebelisoa theknoloji ea ts'ebetso ea UNIPOL™.E reretsoe ho sebelisoa lits'ebetsong tsa liphaephe moo matla a nako e telele a hydrostatic le ho hanyetsa ho hola butle ha crack ho lakatsoang.Lisebelisoa tse loketseng li kenyelletsa lipeipi tsa kabo ea khase ea tlhaho, lipeipi tse kholo tsa liindasteri tse bophara bo boholo, merafo, likhoerekhoere le likhoele tsa litšebeletso tsa metsi tsa masepala.Tumellano ea Maemo a Indasteri: ASTM D 3350: sehlopha sa lisele - Tlhaho - PE345464A - Black - PE345464C (Sheba LINTLHA A) Plastics Pipe Institute (PPI): TR-4 - Natural Pipe - DGDB-2480 NT 3408 - ASTM PE3608 pipe ea HDsi grade 0p @ 73°F – Pipe e Ntsho – DGDB-2480 BK 3408 (Sheba LINTLHA B) — ASTM PE3608 phaephe ya grade – 1600psi HDB @ 73°F le 800psi HDB @ 140°F National Sanitation Foundation (NSF) Standard 14 le 61 – Natural Pipe – DGDB-2480 NT 3608 – Black Pipe – DGDB-2480 BK 3608 (Sheba LITLHAKISO B) Sheba melaoana bakeng sa lintlha tse felletseng.LINTLHA TSEO: (A) Linomoro tse hlano tsa pele tsa sehlopha sa lisele li thehiloe holim'a resin ea tlhaho.Nomoro ea ho qetela le tlhaku li thehiloe holim'a resin e ntšo (resin ea tlhaho hammoho le 6.5% DFNF-0092).(B) Resin ea tlhaho e fetisitsoe tlas'a maemo a nepahetseng ka carbon black masterbatch DFNF-0092 (6.5%).

Lisebelisoa

Likopo tsa 1.Pipe

2.Lipeipi tsa kabo ea khase ea tlhaho

3.Large bophara ba liphaephe tsa indasteri

4.Moepo

5.Likhoerekhoere

6.Lithapo tsa litšebeletso tsa metsi tsa masepala

HDPEBellows, e tsejoang e le PE curragted pipe, ke mofuta o mocha oa phala e khanyang e entsoeng ka polyethylene e phahameng.

Bophara ba marako a marako a mabeli a HDPE a hlahisoang Chaena ke φ400 ~ φ1400mm, e sa hlokeng feela metsi a mangata a lisebelisoa ho finyella litlhoko tsa ho sebetsana le lisebelisoa, empa hape e finyella litlhoko tsa boleng ba ho satalla ha lihlahisoa (sehlopha sa S2 se seholo ho feta 8KN /m2, bakeng sa thepa e itseng, bophara bo boholo, bo theola boleng ba ho satalla ha selikalikoe. Kahoo sena se tlisa bothata bo itseng tabeng ea ho khetha thepa.Ka mor'a liteko tse ngata, Qilu HDPE2480 e ka finyella litlhoko tsa eona tsa tlhahiso, empa ho satalla ha selikalikoe sehlahisoa se ke ke sa fihla ho 8KN / m2. Teko ea ho satalla ha lesale ka mocheso o tloaelehileng (23 ± 2℃) ke 6.2kN / m2, e hlokang ho fetoloa ha thepa le ho hloka hore ntle le ho fokotsa ts'ebetso ea HDPE2480 ea pele. tlas'a boemo ba ho netefatsa ho feto-fetoha ha selikalikoe, tšusumetso e tlase ea mocheso le matla a matla a sehlahisoa;

Ts'ebetso ea ho tlatsa e phahameng e fetotsoeng masterbatch ea melomo e meholo ea polyethylene e ka fihlelang litlhoko tsa ho feto-fetoha ha selikalikoe se seholo sa caliber, tšusumetso e tlase ea mocheso, matla a tšusumetso ea notch le lefu le itseng la ho kobeha.

E kopantsoe le 30-50% D50 = 2-7 μm ultrafine calcium carbonate le 50-70% ultrafine talc powder, phofo e kopantsoeng e ile ea lokisoa.

Palo e tlatsitsoeng ea lisebelisoa tse hloahloa tse entsoeng ka thepa e kopaneng ea phofo e ka fihla ho 50% ka melumo e kholo ea HDPE.Tlas'a boemo ba HDPE∶ lisebelisoa tse ncha tse fetotsoeng = 50∶50, boima ba phala e nang le caliber e tšoanang bo eketseha feela 5 ~ 6%, 'me modulus ea eona e kobehang e fihla ho 1360Mpa.Ho hanyetsa matla le tšusumetso ea thepa e nang le matla a flexural a 24Mpa e tšoana le ea thepa ea pele e fetotsoeng ha e tlatsitsoe ka 30%: matla a thata ke ≥24Mpa, le palo ea ho phatloha ha 10 sampuli e nang le ts'oaetso ea tšusumetso ho 0 ℃ e ka tlase ho 1, e fihlelang ka botlalo litlhoko tsa boleng ba melumo e meholo ea HDPE.

E sebelisa 30 ~ 50% D50 = 2 ~ 7μm superfine calcium carbonate le 50 ~ 70% superfine talc powder ho kopanya phofo e nang le likarolo tse 100, ho eketsa 0.2 ~ 1 karolo e kopanyang ka har'a phofo e kopantsoeng le ho hlohlelletsa metsotso e 5 ~ 10 120 ~ 140 ℃.Ebe u eketsa likarolo tse 3 ~ 6 tsa oli e tšoeu, 1 ~ 2 likarolo tsa stearic acid, 1 ~ 2 likarolo tsa oli ea silicone ea hydroxyl le likarolo tse 20 ~ 30 tsa polyethylene kapa polypropylene e tsosoa ka mokhoa o ts'oanang ka mor'a thepa, mocheso oa 150 ~ 190 ℃, ka parallel twin screw extruder extrusion ea eona e tsoakiloeng le granulating.

E le ho kopanya boholo ba masterbatch le ho fokotsa litšila le lerōle ts'ebetsong ea tlhahiso, masterbatch e khaoloa le ho hlahlojoa ke moea ho fumana boholo bo lekanang ba likaroloana.

Moemeli oa khokahanyo ke titanate coupling agent kapa aluminate coupling agent kapa silane coupling agent.