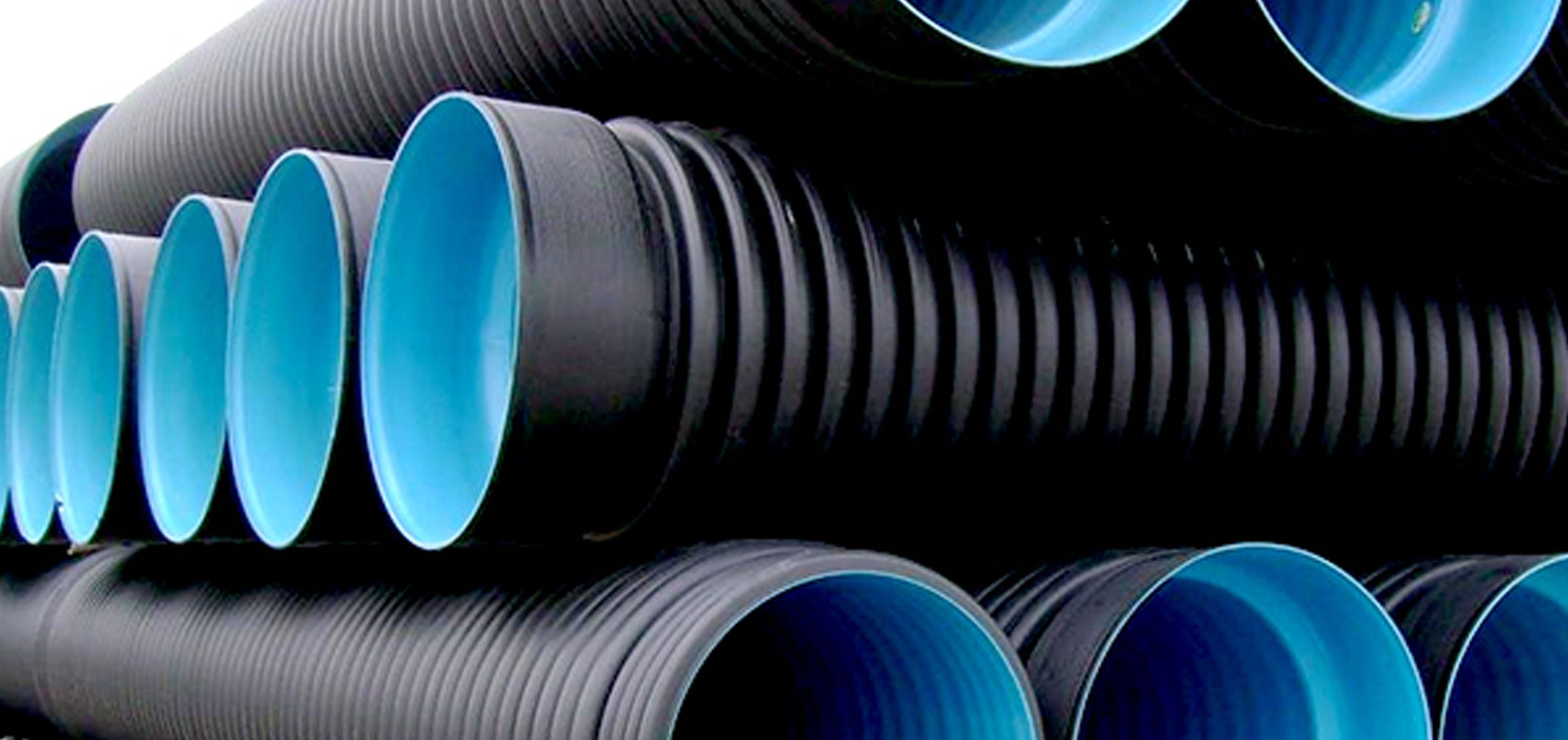

HDPE habeli lebota masenke phala thepa e tala

HDPE marako a mabeli a entsoeng ka lipeipi tse tala,

HDPE bakeng sa tlhahiso ea lipeipi tse entsoeng ka marako a mabeli, Ke mofuta ofe oa resin ea HDPE e sebelisetsoang phala e entsoeng ka marako a mabeli,

HDPE habeli lebota masenke phala thepa e tala

1. Sebopeho sa lisebelisoa tse tala: Lisebelisoa tse tala tsa PE tse nang le marako a mabeli hangata li entsoe ka polyethylene, lisebelisoa tse ntlafetseng le li-pigments.Haeba thepa e tala e le metsi, e le ho ntlafatsa katleho ea tlhahiso, ho ka eketsoa defoamer e nepahetseng.

2, litlhoko tsa ts'ebetso ea lisebelisoa tse tala: mokhoa oa ho hlahisa theko e tlase, melumo ea boleng bo holimo, e itšetlehile haholo ka khetho ea thepa e tala le collocation ea foromo.

Litlhoko tse akaretsang tsa ts'ebetso ea polyethylene (PE) li kenyelletsa tekanyo ea ho phalla ha metsi (MFR), nako ea ho kenya oxidation (OIT) le letsoalo.Boholo ba sekhahla sa ho phalla ha metsi se bonahatsa boholo ba boima ba molek'hule.Ka kakaretso, thepa e nang le sekhahla sa phallo e phahameng ea ho qhibiliha e thusa ho sebetsa le ho theha, 'me e ka ntlafatsa

katleho ea tlhahiso.Leha ho le joalo, e ke ke ea e-ba kholo haholo, e nang le tšusumetso e kholo ho satalla ha selikalikoe.Ho loketse ho khetha pakeng tsa 0.8-1.5g/10min(190℃, 5kg).Nako ea ho kenya oxidation e lekanya nako ea tšenyo ea oxidation.Bakeng sa melumo e hlokang lilemo tse 50 tsa ts'ebeliso, ho laola nako ea tlhahiso ea oxidation ea lisebelisoa tse tala ke senotlolo sa ho netefatsa bophelo ba ts'ebeletso ea lilemo tse 50.Ho boletsoe ka ho hlaka ho GB/T19472.1-2004 hore nako ea ho kenya oxidation ea lihlahisoa tse tala e lokela ho ba ≥20min (200℃).Bakeng sa polyethylene e bohareng le e phahameng, thepa ea eona e ka fetoloa ka ho fetola boima.Hobane rea tseba hore polyethylene e fokolang haholo e ka lelefatsa nako ea eona ea ho hloleha ho brittle.

katleho ea tlhahiso.Leha ho le joalo, e ke ke ea e-ba kholo haholo, e nang le tšusumetso e kholo ho satalla ha selikalikoe.Ho loketse ho khetha pakeng tsa 0.8-1.5g/10min(190℃, 5kg).Nako ea ho kenya oxidation e lekanya nako ea tšenyo ea oxidation.Bakeng sa melumo e hlokang lilemo tse 50 tsa ts'ebeliso, ho laola nako ea tlhahiso ea oxidation ea lisebelisoa tse tala ke senotlolo sa ho netefatsa bophelo ba ts'ebeletso ea lilemo tse 50.Ho boletsoe ka ho hlaka ho GB/T19472.1-2004 hore nako ea ho kenya oxidation ea lihlahisoa tse tala e lokela ho ba ≥20min (200℃).Bakeng sa polyethylene e bohareng le e phahameng, thepa ea eona e ka fetoloa ka ho fetola boima.Hobane rea tseba hore polyethylene e fokolang haholo e ka lelefatsa nako ea eona ea ho hloleha ho brittle.

Boemo ba pipe ea HDPE bo na le kabo e pharaletseng kapa ea bimodal ea boima ba limolek'hule.E na le khanyetso e matla ea creep le botsitso bo botle ba ho tiea le ho tiea.E tšoarella haholo 'me e na le sag e tlase ha e sebetsoa.Liphaephe tse hlahisoang ho sebelisoa resin ena li na le matla a matle, ho tiea le ho hanyetsa tšusumetso le thepa e ntle ea SCG le RCP..

Resin e lokela ho bolokoa sebakeng sa polokelo se omeletseng, se omeletseng le hole le mollo le khanya ea letsatsi.Ha ea lokela ho bokelloa sebakeng se bulehileng.Nakong ea lipalangoang, thepa ha ea lokela ho pepesetsoa letsatsi le matla kapa pula 'me ha ea lokela ho tsamaisoa hammoho le lehlabathe, mobu, litšepe, mashala kapa khalase.Lipalangoang hammoho le lintho tse chefo, tse senyang le tse tukang li thibetsoe ka thata.

Kopo

Boemo ba liphaephe tsa HDPE bo ka sebelisoa ho hlahisa liphaephe tsa khatello, tse kang liphaephe tsa metsi tse hatelitsoeng, liphaephe tsa khase ea mafura le liphaephe tse ling tsa indasteri.E ka boela ea sebelisoa bakeng sa ho etsa liphaephe tse se nang khatello tse kang lipeipi tse nang le mabota a mabeli, lipeipi tse pota-potileng lebota, lipeipi tsa silicon-core, lipeipi tsa nosetso tsa temo le lipeipi tse kopantsoeng tsa aluminiumplastics.Ho feta moo, ka extrusion e sebetsang (silane cross-linking), e ka sebelisoa bakeng sa ho hlahisa liphaephe tsa polyethylene (PEX) tsa crosslinked polyethylene (PEX) bakeng sa ho fana ka metsi a batang le a chesang.